Ok, update time!

Was restless after work, so decided to dig into this project again.

I decided to test a theory, and see if the Sentra starter would engage the ring gear on the flex plate I have, since my cad models showed it as being possible, and the diameter difference of the ring gears was only 0.046", the Sentra one being the smaller one.

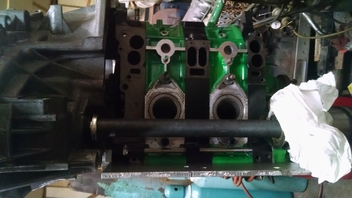

I split the transmission back in half again, to make it more manageable, and set the bellhousing side down on the engine while it was on the stand.

I used some 3/8" tool steel blanks as spacers initially.

I used the automatic flex plate that came with my counterweight for the trial run, since the ring gear is the same as the one on an RX-7 Turbo flywheel. It was just set on the locating boss of the counterweight without any bolts, so it could spin freely.

I had clearance between the ring gear and trans housing, and could spin the flex plate by hand without anything hitting.

I then jammed the starter bendix in the max outstretched position with a chunk of wire between the sprag clutch and housing, and set it in place on the trans.

It's a bit hard to see, but there is engagement, and rotating the starter back and forth moved the flex plate.

(Below photo is with 1/2" bar stock spacers, I didn't document the initial "Eureka!" moment)

Needless to say, I did a happy dance.

Then I remembered my adapter plate is going to be 1/2", not 3/8", and to confirm that it works, I should make sure I have the input shaft bearing bore concentric with the eccentric shaft.

To maintain alignment, I turned up a quick centering jig out of aluminum round stock, with a 15mmx25mm end teat to match the pilot bearing in the eccentric shaft, and the rest 1.03" diameter to be a close slip fit into the clutch release tube of transmissions housing.

Now I did another happy dance, since my findings were verified.

This is a crucial development, since now I know that I can use an RX-8 or RX-7 Turbo aftermarket flywheel (Looking at an aluminum one, either Fidanza or Racing Beat), stuff the Sentra clutch disc in, and use an RX-8 or RX-7 Turbo pressure plate.

I'll need to make a spacer for the flywheel, but that won't be difficult.

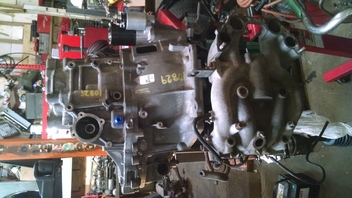

I then decided to check CV jackshaft clearance again, since now I have the trans concentric.

That meant plopping the differential back in and putting the rear case back on.

Surprisingly, I have enough clearance between the jackshaft bearing and the front cover.

(photo rotated to "normal" driveline view)

This is another good thing, since it means I don't have to modify the jackshaft on the CV, and can probably get away with using the entire unit as-is.

I then decided to test-fit the lower intake, and found that one of the nipples hits the transmission.

Hacksaw time. I'll pull it fully later.

I'll be honest, and say I can't remember what it goes to, or what function it has.

It routes back to the ACV mounting area on the manifold.

A few pics with the middle intake and starter on, rotated to put the transmission on the proper side.

I'm going to be ordering either a Fidanza or Racing Beat aluminum flywheel, and will use that to verify a few more dimensions.