Well, it's been about 6 months since I cut my first 1.25" square tube and I figure I am about due to post an update here! Thanks to so much to Lonnie who wrote me back regarding a few things and a big shout out to Jack McCornack at kinetic. Jack has come though with some great advice and some great parts. I'm buying all I can from him due to his great support here and personally.

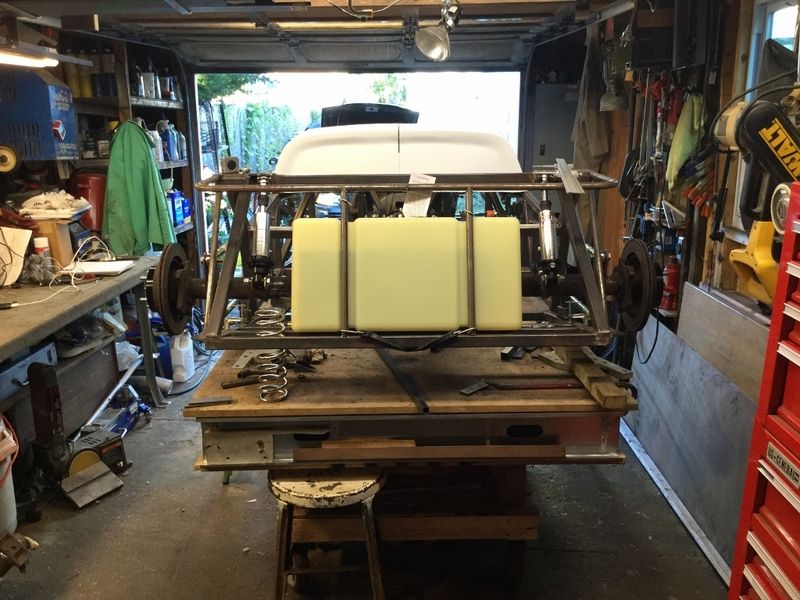

My table has worked out great; still super flat and sturdy. With it's big wheels I can roll it easily in and out of my garage (very helpful during the engine swap) and the industrial machine levelers on 4 corners make it easy to have a level table to work from.

I went with the Griggs SN95 SLA adaptors; Bruce Griggs has been super helpful. I like that they are steel and that there are three bolts holding it to the SN95 spindle instead of only two bolts on other adaptors. I did need to ream out the lower ball joint holes with a 7 degree reamer for full taper engagement (thanks for the hard work researching this Lonnie!).

I really wanted to use the SVT Cobra's quick ratio steering rack, but in the end it was easier for me to buy a new 5" shortened Flaming River manual rack. Thus far my geometry looks good and bumpsteer has been pretty much adjusted to the best I can see with a long straightedge. I'll be setting up a laser to see where I'm really at when I return to the US in November.

Note that some of the frame is fully welded, actually a LOT of the frame is fully welded, but the tunnel area and some of the suspension bits are just temporarily tacked in place until I figure out where other stuff goes.

I went with long links (~31") due to influence from Cheapracer. Look cool in my opinion and it's fun to be different. I will eventually mount the link bolts in double shear with a bracket (this is what the forward holes are for).

I also made a nice set of geared Cheapracer BEX link, but in testing I found that it allowed my axle to rotate a bit too much around the BEX center point. This is a great attribute for most, but for me with really big tires and tight body clearance I could see how my tires will rub the body at their tops. I made a long track bar instead and this seems to better suit my situation. If anyone needs a set of BEX links please let me know!

I am using a 10 gallon JAZ cell from Jack and will mount the SVT Cobra fuel pump inside it.

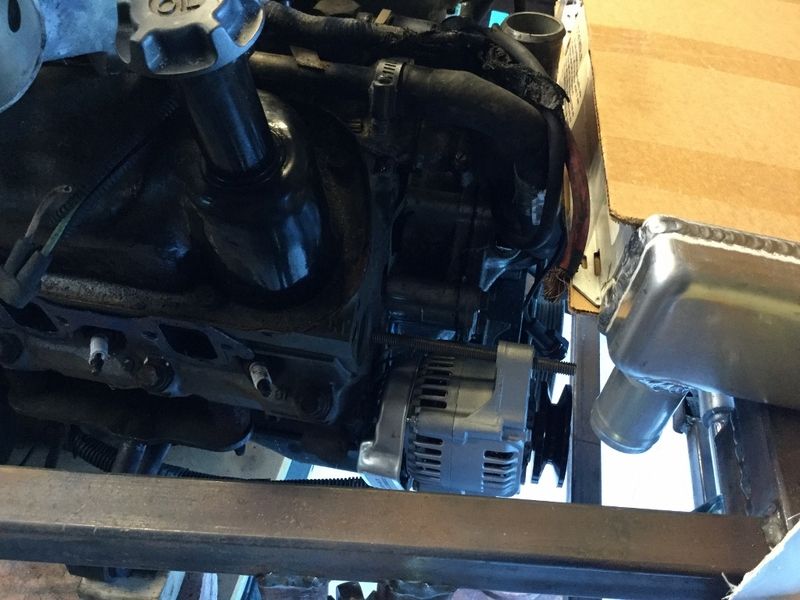

I also picked up a 70A Denso style alternator to help with the space around the engine.

Luckily I drove the SVT Cobra before I took it apart and everything works great! Fresh "real" GT40 heads, ported along with the Cobra intake. E303 cam and 3.73 gears. Even with the big tires it would break them free at full throttle in 2nd gear. It has the original SVT T5 with phosphated gears and it shifts awesome! I'll be using a hydraulic throughout beating actuator to save some space in the tunnel and with some good planning I'll be able to fit some decent size pedals (11E shoes) and 18" Kirkey Pro Street drag seats.

I also plan on going the Megasquirt MS3-Pro route and use most of the Cobra hardware.

Because I travel out of the country for work 9 months out the year, I don't have much time to work on the car, but I do have time to plan, think, and order stuff on the internet!

Thanks to all others here on Locostusa! Your hard work and constant sharing of information has made this project possible for me. I cannot thank you all enough!