Lonnie-S wrote:

If you're going with an IRS, I can't be of much help as I have a live, 7.5" Mustang rear axle from a 1994. I can't tell you which IRS rear axles will work best. Is that the question you want answered?

He's asking how much space he needs between the inside face of the wheel/tire and the frame.

https://trackmustangsonline.com/threads ... nce.13708/5mm is enough, 10mm is plenty. You'll want to check the arc of your suspension travel and see how much the wheel moves in and out.

MacGyver wrote:

I beleive Rod's build used a couple drivers side explorer axles, but I can't find the lengths listed on them.

It's not clear if you're talking solid rear or IRS. Rod used a solid rear axle.

Per RockAuto, the Explorer axles are:

Right: 27-13/16" long

Left: 30 11/16" long

Quote:

When my frame is 46" wide, and the wheel mounting surfaces are coming out to around 63-1/2" it seems to me that I'm going to need nearly 3.5" of offset in my wheels to get them within 1-1.5" of the frame. Am I missing something, or (sorry to be lazy) can someone just tell me what axles to look for that will work with my 31 spline rear end? I'm looking to use 17x9 rims in the rear.

The Explorer rear end has an offset pumpkin. You can cut the long side to make it the same width as the short side and use a short side axle. Then your WMS-to-WMS measurement is 56.5". Stock Thunderbird IRS WMS wider than that.

TRX, I understand the mustang has been used plenty, but the one I was specifically mentioning was a 2015-18 rear setup. I'm not comfortable walking up to a strangers car and crawling under it. [/quote]

Search car-part.com for 2015 Ford Mustang Rear Suspension, then choose "Complete Assembly." Every 2015-up Mustang has a limited slip, the engine, trans, and PP will just dictate gear ratio.

Any vendors selling Mustang upgrades would be a good place to see pictures of suspension components.

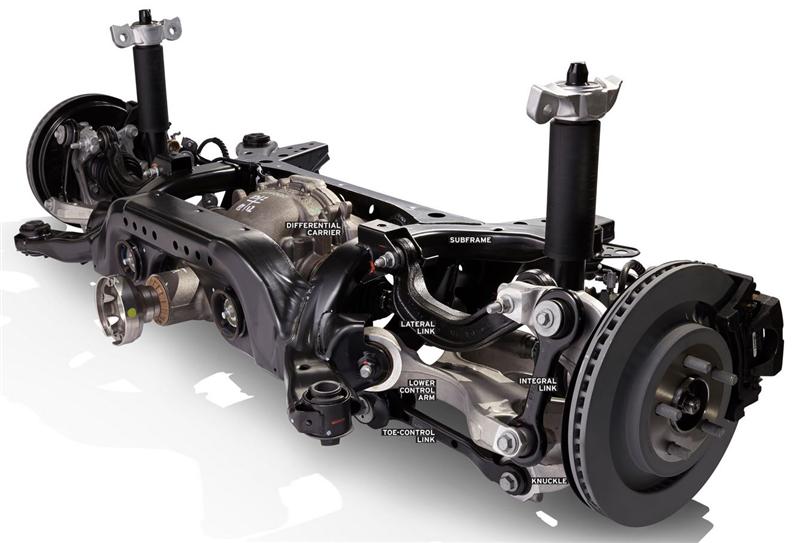

Here are some good pics of the IRS assembly:

https://thefactoryfiveforum.com/showthr ... -it-beginsYou can find them under $600 for an 8.8 LSD, IRS, disc brakes, and axles that can hold 500+hp on a 3800lb car. Overkill and too wide for a basic Locost but surely an awesome option for a vintage retrofit.