After reaching the milestone of "rolling" it around (and possibly making Vroom Vroom noises...

) I decided to carry on with getting the frame as close to done as possible. That meant taking everything back off and getting it to where I could flip it upside down or on it's side, depending on what I'm working on.

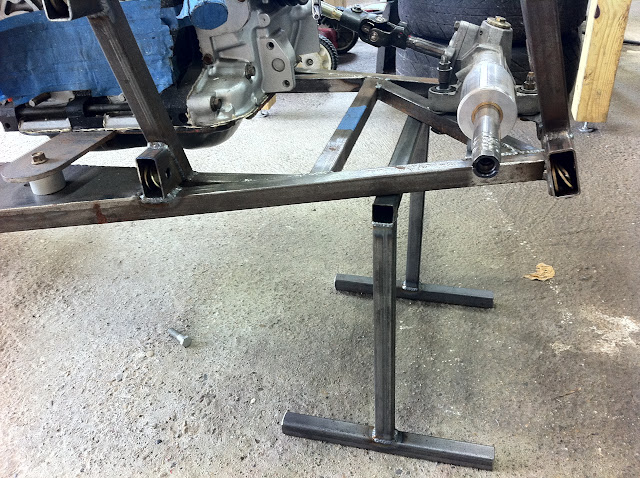

I already had a set of jack stands kicking around in the garage, so I used those for the back. I decided instead of buying another pair of jack stands, I could make something simpler and sturdier out of material I had laying around. So I used my floor jack to set the height, jacking it all the way up and making the front stand height even with the back. This way I can use just a normal floor jack to put the car up on the high stands. It's a good height for working in the engine bay comfortably standing, while using a roll-around stool for servicing brakes/suspension, plus it's high enough to be able to lay under the car to change fluids and work under the car.

Pic of the car on my homemade high stand

Simple and solid

Jack stands at the back of the chassis

Welded an 1/8" wall section of tubing into the frame rails that the trans mount bolts go through to keep the bolts from squishing the tubes as the bolts are tightened. On the mount side the sleeve was welded flush and ground smooth, on the under side I left 1/8" sitting proud to be able to weld it a bit better. Here is the bottom side.

And here is the smooth mount side.

And here they are with the trans mount installed

Another view of the trans mount

Since the frame was bare again, I did some more finish welding. Specifically the bottom rails which were then ground smooth to make room for the floor pans. More on this later. Here is the under side of the motor mount plate (the top side is fully welded too, don't know why I bothered but it didn't look right without something underneath.

Welded the driver's firewall (obviously the frame is upside down in the pic)

Again, here's a view from underneath. This is my front shock mount that is welded in two full planes on the outer frame rail, but thought this "tension strap" could help carry the load to another rail and further beef-up the shock mount, as a LOT of load will go through this guy.

Finally got around to cutting my steel floor plates. I decided on steel mainly due to cost, but also ease of installation and potentially better structural properties with steel vs alum. I don't mind the approx 15 pound weight penalty, as long as it's very low in the chassis and helps structural rigidity (I know this is up for debate

)

Another view of the floors with the Aussie Mod front section.

A view of the trans mount bolts and how the floor pans wrap around the protruding "sleeves"

Unfortunately I ran out of gas

so I couldn't weld the floor yet. But it's ready to go otherwise. Going off recommendations I read here, I decided to take the floors all the way out to the edge to make the side panel installation easier down the road.

_________________

-Emile

Scratch building an IRS, RX-7 based book chassis @ my

Build Log*Make way for the luckEseven!