Well I got laid off last week due to COVID and the collateral damage it's caused in my sector, so I have decided to busy myself with this build. I bought this ambulance from a firehall just before COVID happened, with plans to gut it and use it to transport the Locost. I had several reasons for this, but the main ones were that I did not want to own a truck to tow a trailer, and you might be amazed how cheap an ambulance can be.

A little about the ambulance, it's a Ford F450 with the Powerstroke 6.7l engine. The mileage and idle hours are high as one might expect, but being an emergency vehicle it's very well maintained. It has a Kelderman 4-link rear suspension with airbags that has a self-leveling feature, and if I can ever figure out how, it's supposed to be able to squat the rear down several inches for loading and unloading. Surprisingly, the lights and siren were still functional, so the first thing I had to do was replace the emergency lights with blanking panels. I will try to sell those off later to offset some of the cost.

Here it is mostly as it sits right now. I left the side and rear flood lights, but removed the nifty remote-controlled spotlight it had on the roof of the cab. It's a little bigger than I wanted (a van-based Type III ambulance would have been more compact) but for the price I just couldn't say no.

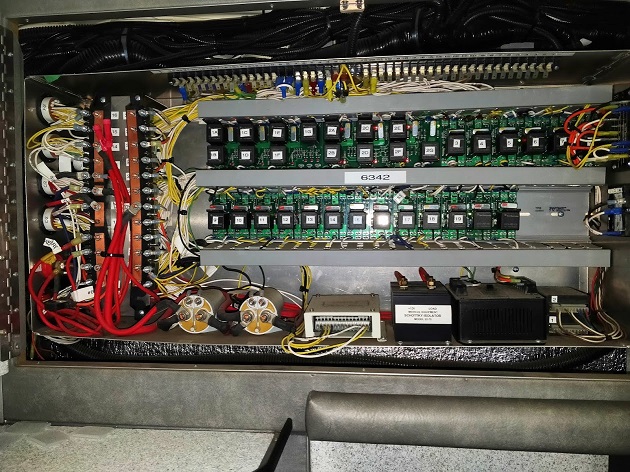

One of the great things about an ambulance is all the electrical is done VERY well. Everything is nicely loomed and labelled so you can trace anything very easily. The thing also came with a binder with complete electrical diagrams!

I couldn't resist using it as a grocery getter just once. I definitely got some strange looks, but it was so easy!

Here's what the interior currently looks like. There are some protrusions from compartments opening to the exterior that I will have cut out next, then patch the floor. I drove the thing over a scale before starting this and it was almost 14k lbs.

Now, the cabinets, counters and everything else I have pulled out so far are all aluminum, but it's all still quite heavy. Everything is built from 1/8" plate. I'm guessing I've removed well over 800 lbs of stuff so far, perhaps more.

So, my next job is to cut out the compartments I mentioned above. Then, I need to widen the rear opening and replace the barn doors with, probably, one large top-hinged door. After that, I plan to build a set of ramps that will permanently sit inside the box and pivot near the back. At the front of the ramps will be a trailer jack and an electric winch. Then I will have some removable ramps that go from the door to the ground, and to load the car I will winch it up the removable ramps onto the raised interior ramps, then use the trailer jack to lower the ramps so the car sits close to level inside.

A list of the interesting things I have found in it so far:

-Fire hydrant wrench

-RF transmitter that might have been a red light changer?

-One IV bag of saline

-One (new) syringe

-One set of scissors for cutting clothing off patients