CS3's projects

Moderators: a.moore, JackMcCornack

- Jawfish

- Posts: 942

- Joined: October 15, 2006, 11:15 am

Wow Rod,

That engine sure does look in good condition from your pics. Keep trhem comming

Are you going to paint the aluminium center section ?

Question about the Se7en... Anything special on the 4AGE-T50 combo in the Lotus frame to whatch out for ? Are using a Regular Lotus nose cone or a modified one ?

Thanks

Fred

That engine sure does look in good condition from your pics. Keep trhem comming

Are you going to paint the aluminium center section ?

Question about the Se7en... Anything special on the 4AGE-T50 combo in the Lotus frame to whatch out for ? Are using a Regular Lotus nose cone or a modified one ?

Thanks

Fred

-

cs3tcr

- Posts: 1045

- Joined: December 29, 2007, 10:41 pm

- Location: Vancouver, BC

Fred,

I'm going to leave the sills on the Eleven in natural aluminium, but paint the doors and scuttle.

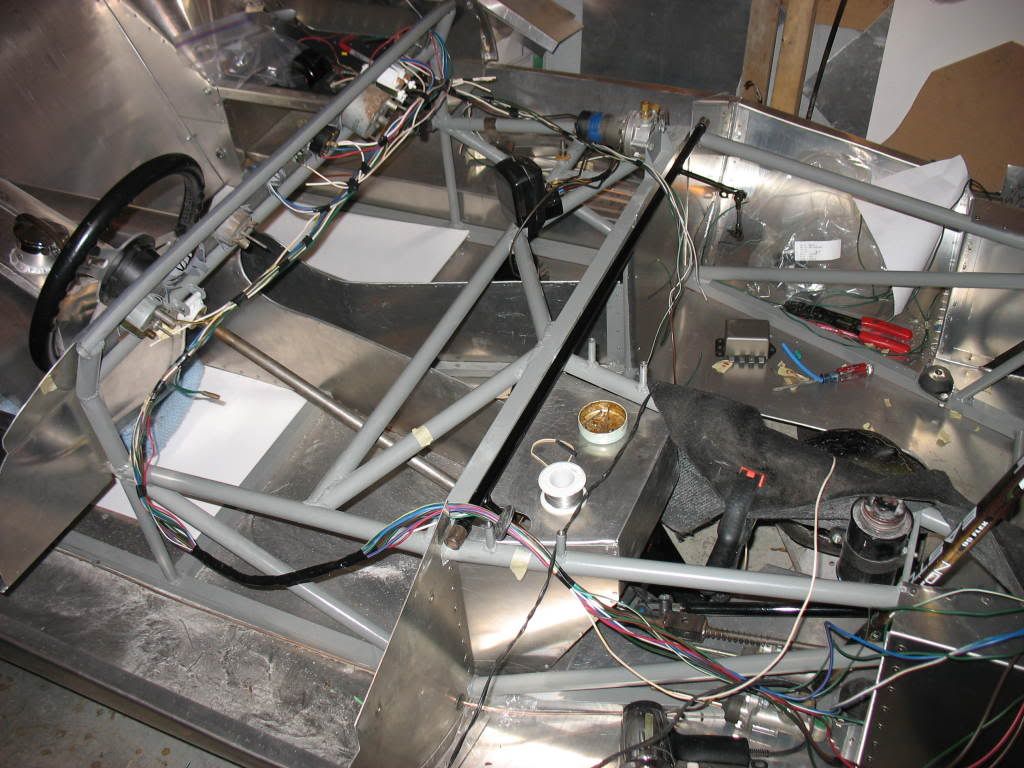

On to the 4AG/T50 questions, i'm using a Lotus nose cone, which is slightly lower than a Caterham one. I wish i had a Cat one when building the car, that way the oil pan wouldnt hang so low. The T50 is shorter than the ford gearbox in respect to the shifter position. If you want the shifter in about the right spot, you have to push the gearbox as far back as you can in the frame. The farther back you go the smaller the pedal box gets. My pedal box just accomidates size 10 shoes.

Cheers,

Rod

I'm going to leave the sills on the Eleven in natural aluminium, but paint the doors and scuttle.

On to the 4AG/T50 questions, i'm using a Lotus nose cone, which is slightly lower than a Caterham one. I wish i had a Cat one when building the car, that way the oil pan wouldnt hang so low. The T50 is shorter than the ford gearbox in respect to the shifter position. If you want the shifter in about the right spot, you have to push the gearbox as far back as you can in the frame. The farther back you go the smaller the pedal box gets. My pedal box just accomidates size 10 shoes.

Cheers,

Rod

-

cs3tcr

- Posts: 1045

- Joined: December 29, 2007, 10:41 pm

- Location: Vancouver, BC

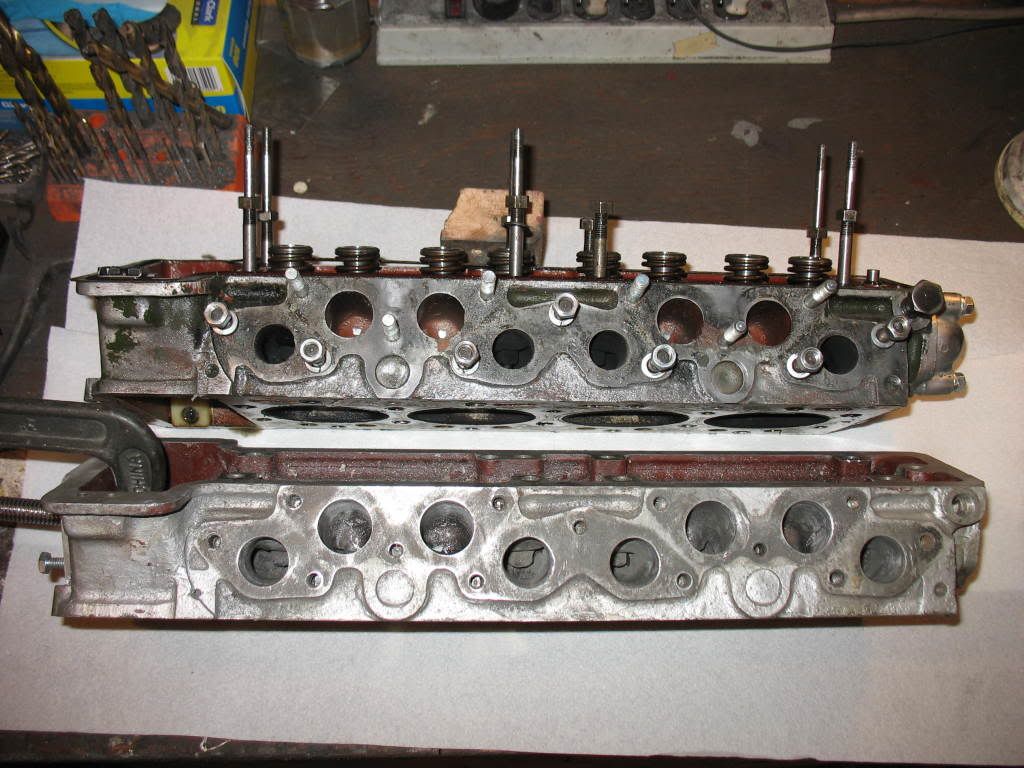

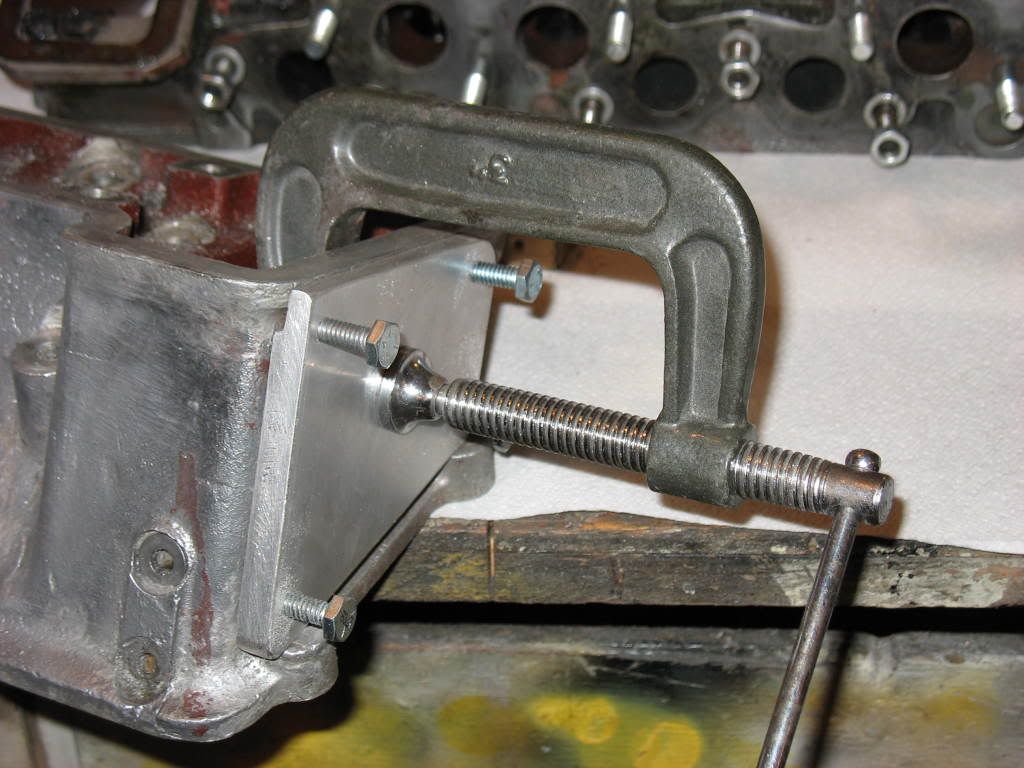

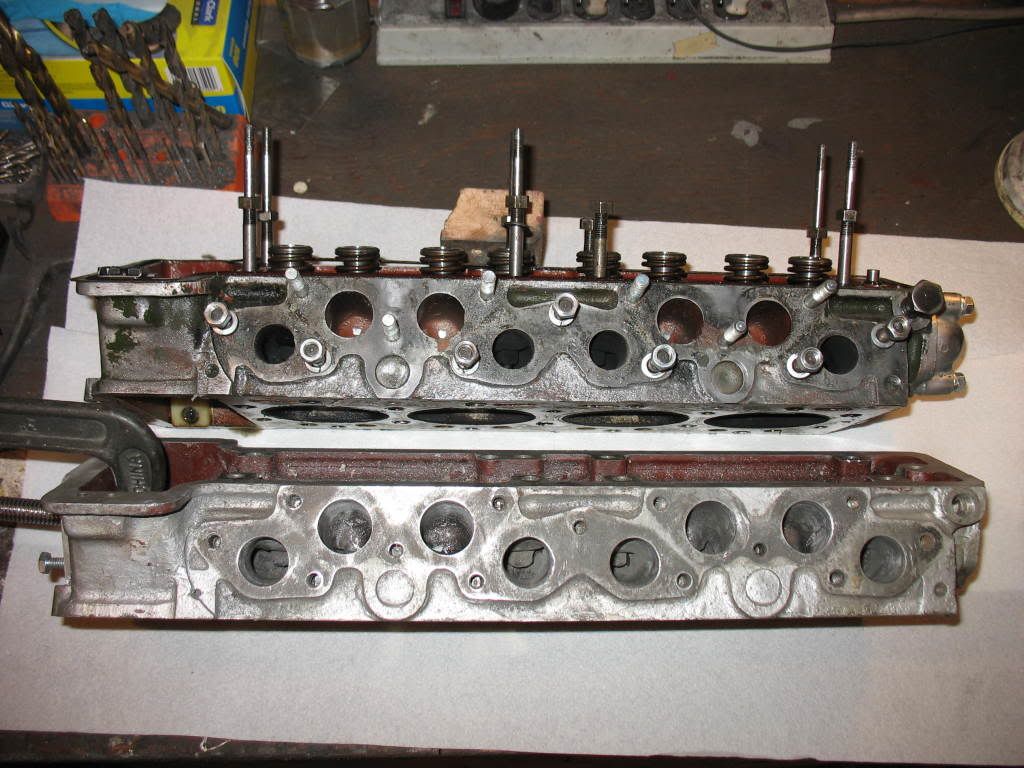

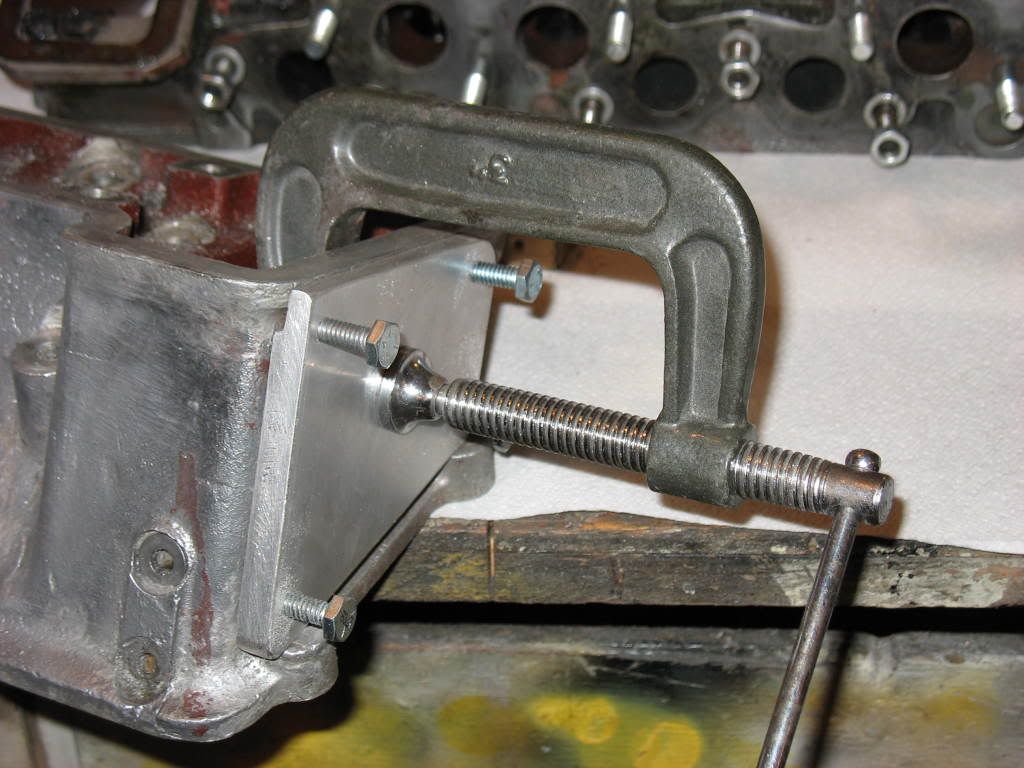

Spent today playing around with the cylinder head. Opened up the exhaust ports .075" and polished both the intake and exhaust ports.

Then made up the generator mount. Going to take it to work tomorrow and have it welded on, then the head is off to the machine shop to get a valve grind.

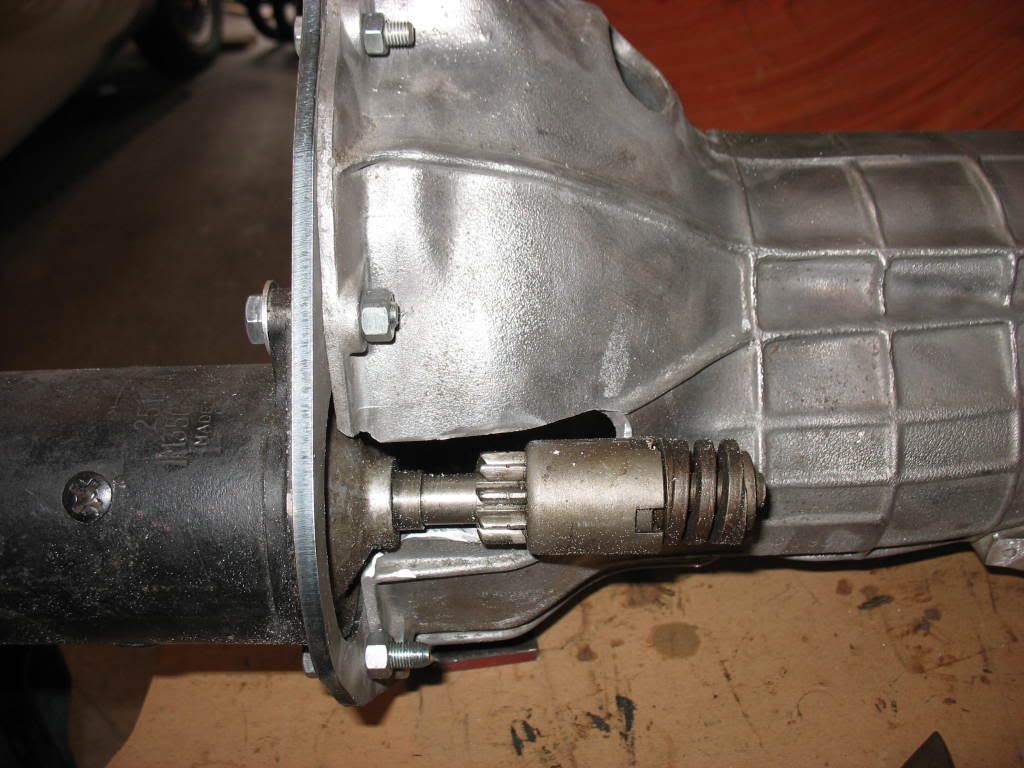

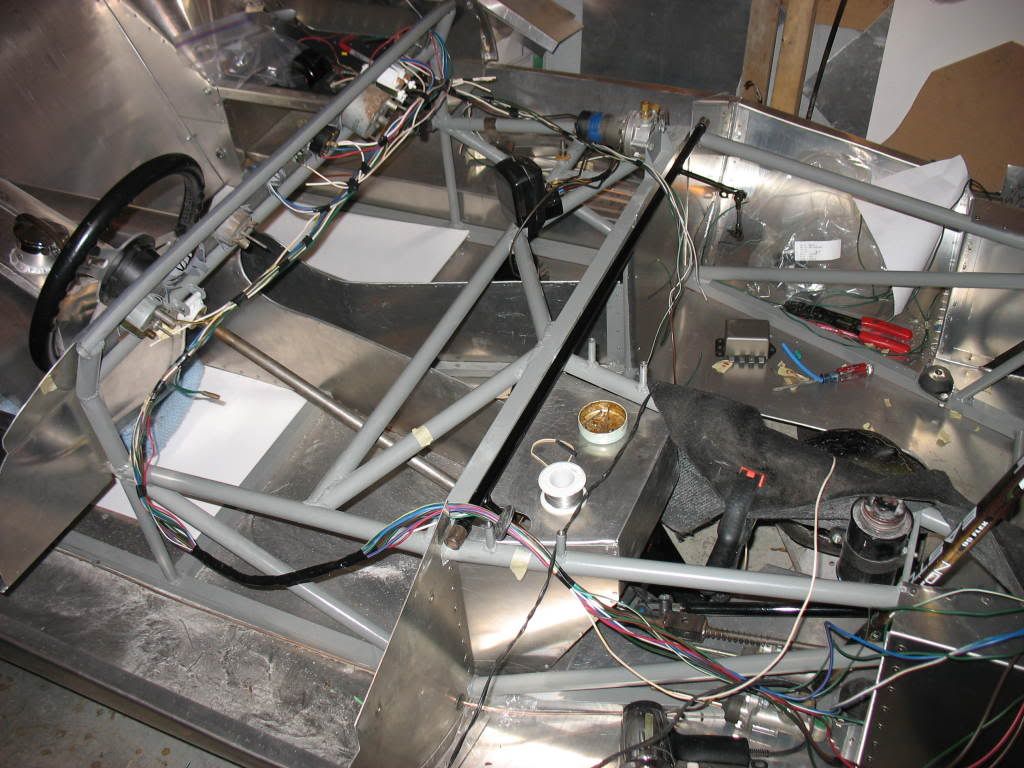

Also, last Thursday and this past weekend i rebuilt the gearbox, cut a notch for the starter bendix and made up the wiring loom for the car. Got the loom all taped up and relized that i didnt include a horn circuit. So, i'll make up a sub harness for the horn, now i just have to figure out where to put it.

I wish i had a photo of the 'box in bits, but i was way to frustrated to be using a camera.

Then made up the generator mount. Going to take it to work tomorrow and have it welded on, then the head is off to the machine shop to get a valve grind.

Also, last Thursday and this past weekend i rebuilt the gearbox, cut a notch for the starter bendix and made up the wiring loom for the car. Got the loom all taped up and relized that i didnt include a horn circuit. So, i'll make up a sub harness for the horn, now i just have to figure out where to put it.

I wish i had a photo of the 'box in bits, but i was way to frustrated to be using a camera.

-

cs3tcr

- Posts: 1045

- Joined: December 29, 2007, 10:41 pm

- Location: Vancouver, BC

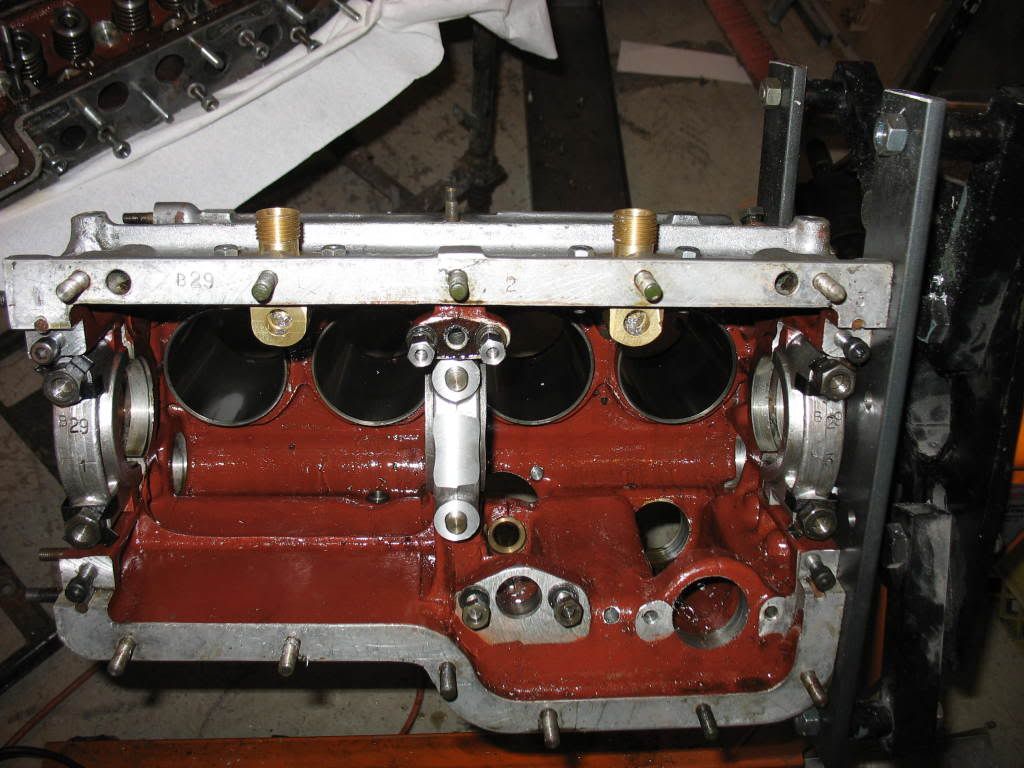

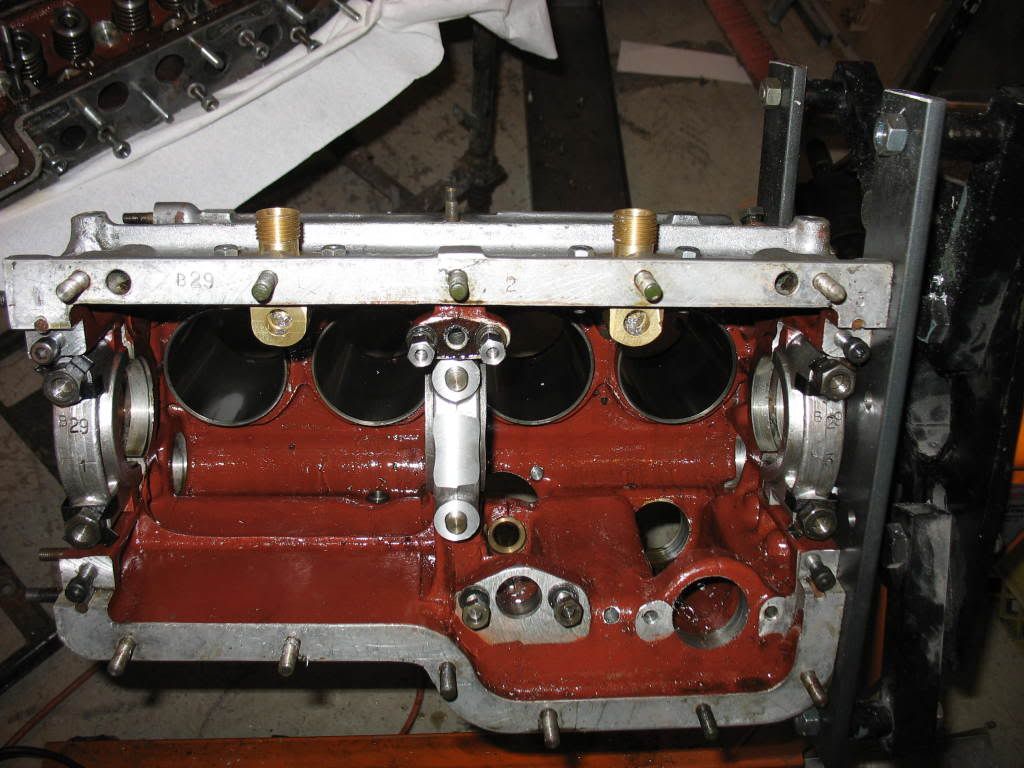

Spent the last couple days having/making up the fittings that pass through the block to allow an oil filter. So today, i drilled through the block to fit them, then cleaned the block to start on rebuilding the motor. I got the crank back in, and installed the jackshaft and timing gears.

This week i'm hoping to get the cylinder head off to the machine shop to fit larger exhaust valves along with planing the head .040" and doing a valve grind. Plus, get the rods crack tested then balance the rods and pistons. Its now looking like i will be able to have the motor done by the middle of December, and maybe running by New Years.

This week i'm hoping to get the cylinder head off to the machine shop to fit larger exhaust valves along with planing the head .040" and doing a valve grind. Plus, get the rods crack tested then balance the rods and pistons. Its now looking like i will be able to have the motor done by the middle of December, and maybe running by New Years.

-

killernoodle

- Posts: 532

- Joined: August 6, 2008, 9:40 am

- Location: Greenville/Charlotte NC

- Miatav8,MstrASE,A&P,F

- Automotive Encyclopedia

- Posts: 8133

- Joined: December 22, 2006, 2:05 pm

- Locost 5.0

- Posts: 682

- Joined: January 7, 2007, 3:24 pm

- Location: Visalia, Ca

Keep the updates coming, they're great. You do awsome work.

Rod

Rod

Driving a +442E with 450 Hp Ford 347 v8, T5, 8 stack EFI w/EDIS8 & MegaSquirt ITB Mode.

12,000+ enthusiastic miles as of 1/1/11

http://www.youtube.com/watch?v=jqvYJlYc4GU

http://s124.photobucket.com/albums/p3/beergodrod/

Now building a 1953 Chevy 1 ton panel with Frito Lay truck parts and a Cummins 4BTA

and a 1963 Nova SS

12,000+ enthusiastic miles as of 1/1/11

http://www.youtube.com/watch?v=jqvYJlYc4GU

http://s124.photobucket.com/albums/p3/beergodrod/

Now building a 1953 Chevy 1 ton panel with Frito Lay truck parts and a Cummins 4BTA

and a 1963 Nova SS

-

Dave

- Posts: 1072

- Joined: August 16, 2005, 10:29 am

- Location: Alberta, Canada

- Contact:

-

cs3tcr

- Posts: 1045

- Joined: December 29, 2007, 10:41 pm

- Location: Vancouver, BC

Just noticed that its been over 2 months since i lasted posted an up date. So, here it goes....

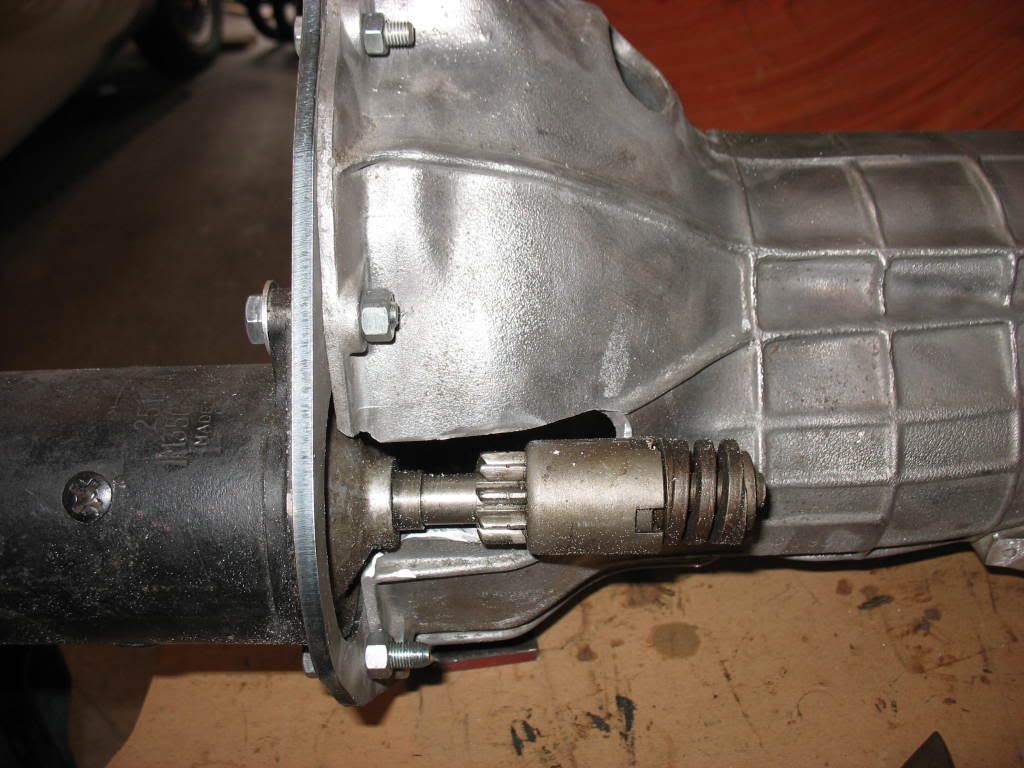

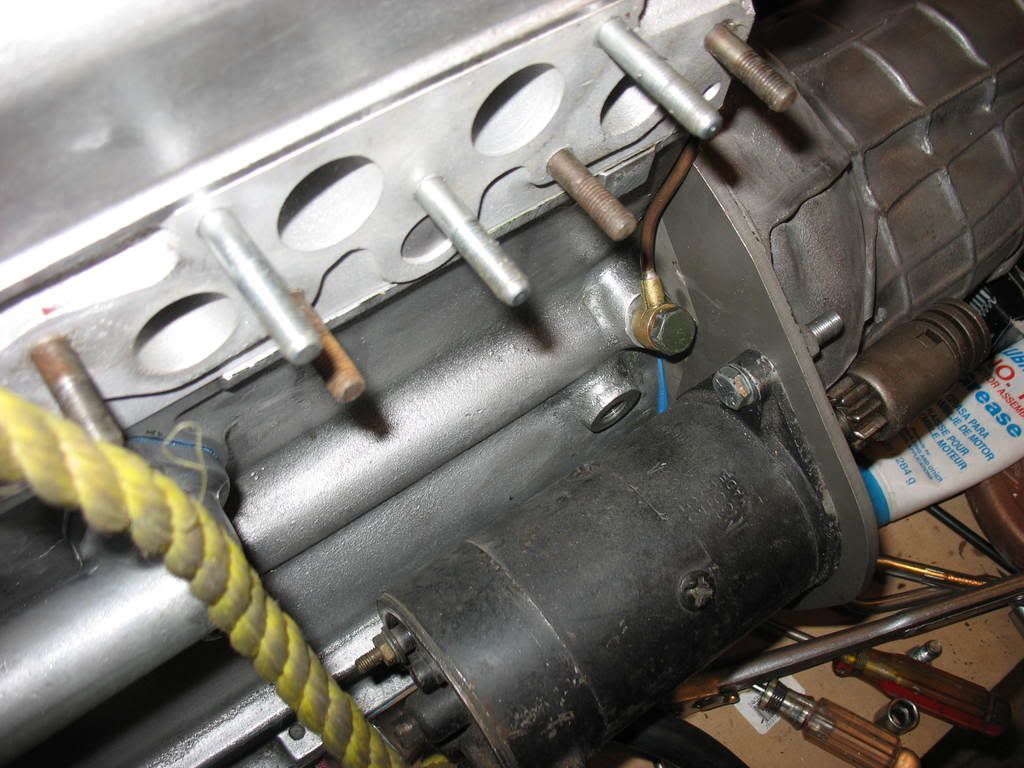

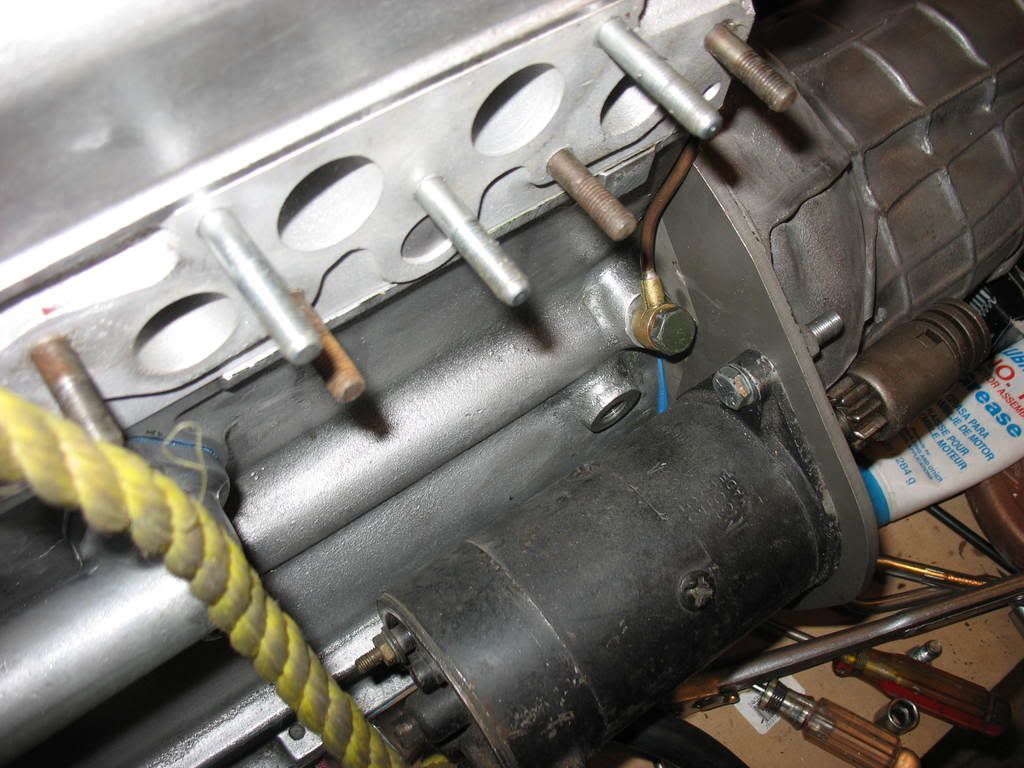

Spent the last month and a bit trying to get the motor done, but kept running into set backs. First, i sent my cylinder head out for machining and 3 weeks later i got it back(should have been back within 1 week in my mind), so that delayed things. Then installed the head and check the valve clearances. Obviously had to order up a complete set, that took only a week (pretty quick i thought). But, i miss measured, one shim was out by .040", so i ordered another bunch (only needed one, but having a selection never hurts). The second batch took 3 weeks (damn postal service). During the delay with the shims, i started to get the rest of the motor ready, i bolted up the fly wheel, tried the transmission on the motor with everything installed, had to relieve part of the bellhousing to clear a bolt, and finally fitted up the oil feed line for the cam and attepted to fit the oil drain back from the head to the block. And thats where the next problem occurred. The starter wont clear the oil line fittings. So, now i'm waiting for a gear reduction starter which is supposed to fit, fingers crossed. Anyways here are some pics, i know the garage looks a mess.

In the last pic you can see the boss for the oil line and the gap between it and the standard Lucas starter.

Spent the last month and a bit trying to get the motor done, but kept running into set backs. First, i sent my cylinder head out for machining and 3 weeks later i got it back(should have been back within 1 week in my mind), so that delayed things. Then installed the head and check the valve clearances. Obviously had to order up a complete set, that took only a week (pretty quick i thought). But, i miss measured, one shim was out by .040", so i ordered another bunch (only needed one, but having a selection never hurts). The second batch took 3 weeks (damn postal service). During the delay with the shims, i started to get the rest of the motor ready, i bolted up the fly wheel, tried the transmission on the motor with everything installed, had to relieve part of the bellhousing to clear a bolt, and finally fitted up the oil feed line for the cam and attepted to fit the oil drain back from the head to the block. And thats where the next problem occurred. The starter wont clear the oil line fittings. So, now i'm waiting for a gear reduction starter which is supposed to fit, fingers crossed. Anyways here are some pics, i know the garage looks a mess.

In the last pic you can see the boss for the oil line and the gap between it and the standard Lucas starter.

-

sevenesqueron

- Posts: 561

- Joined: December 30, 2007, 1:21 am

- Location: North Van., BC

CS#'s projects

Hi Rod,

Despite your setbacks this project has really moved along. It doesn't seem all that long ago that you were just getting going on it.

What army was still using units with 55 year old engines in them and how did you find it?

Ron

Despite your setbacks this project has really moved along. It doesn't seem all that long ago that you were just getting going on it.

What army was still using units with 55 year old engines in them and how did you find it?

Ron

-

cs3tcr

- Posts: 1045

- Joined: December 29, 2007, 10:41 pm

- Location: Vancouver, BC

Re: CS3's projects

After two days of struggle, this has finally happened:

http://s212.photobucket.com/albums/cc171/HockeyRoddy/?action=view¤t=MVI_0954.flv

Turns out that $0.60 of o-rings can make a motor not run. And yes i should have bolted it into the cradle, lol.

http://s212.photobucket.com/albums/cc171/HockeyRoddy/?action=view¤t=MVI_0954.flv

Turns out that $0.60 of o-rings can make a motor not run. And yes i should have bolted it into the cradle, lol.

- a.moore

- Always Moore!

- Posts: 4083

- Joined: November 9, 2007, 3:40 pm

- Location: Pittsburgh, PA

Re: CS3's projects

Happens to the best of us. Props on getting it running.

How much is left until you'll be driving?

How much is left until you'll be driving?

Who is online

Users browsing this forum: No registered users and 1 guest