Warren, vroom; thanks for your thoughts

....i appreciate it

Warren

over the years i learned to look at every bend as a weakness (under very high load),

and my cars evolved to a almost "zero bend" structure.

like this mid-ship engine "Truggy" that i called V-Rex (for

velocity rex due to its massive HP/torque engine):

http://www.supermotors.net/getfile/779727/original/dscf1674.jpgshe is a big girl ; to give a scale i may add that the tires are 40+ inches tall

notice that there are only 2 bends in the main passenger tub/cage structure (at the roof leading edge)...

the nose, sidesteps and tail are kinda built to be "expendable" in a severe crash

so this BEC is my first try at a "large radius tube" structure

and the possible "balloning" of the upper tubes in a straight frontal (or rearend) crash is concerning me a little

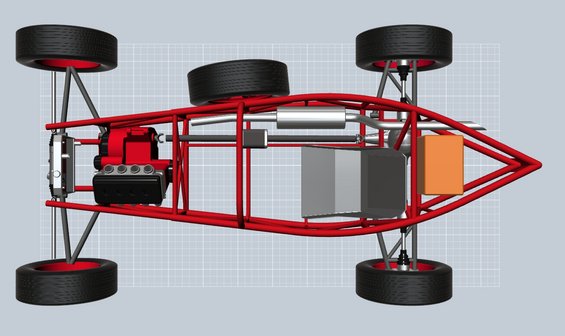

here is a "bird view" screenshot;

high res:

http://www.supermotors.net/getfile/1011085/original/ar6.jpgthe bottom tubes are well restrained with cross-tubing and (most likely) "welded in place" steel floor panels.

however, the upper radi is for large parts unrestrained ....

.... maybe i`m just "overthinking" this

vroom

the drawing is still largely unfinished ... especially the nose and rear are missing several braces

(the fuel tank will also get more surrounding protection)

yes, the tubing is probably grossly oversized (compared to other locosts)

i gave up on building a "super lightweight" BEC mainly for the reason that i want to be able to take this car off the road if i desire.

this is also the reason why i plan on conventional (exposed) coilover shocks;

so that i can adjust the coil preload (ride height) from the outside in a couple minutes.

btw

yes, that`s a spare tire in the drawing

again, i borrowed the idea from the original :

a must for extended off-road excursions but i`m thinking to add a "hitch tubing style" kinda thing,

so that i can remove the tire and its supporting structure for normal driving