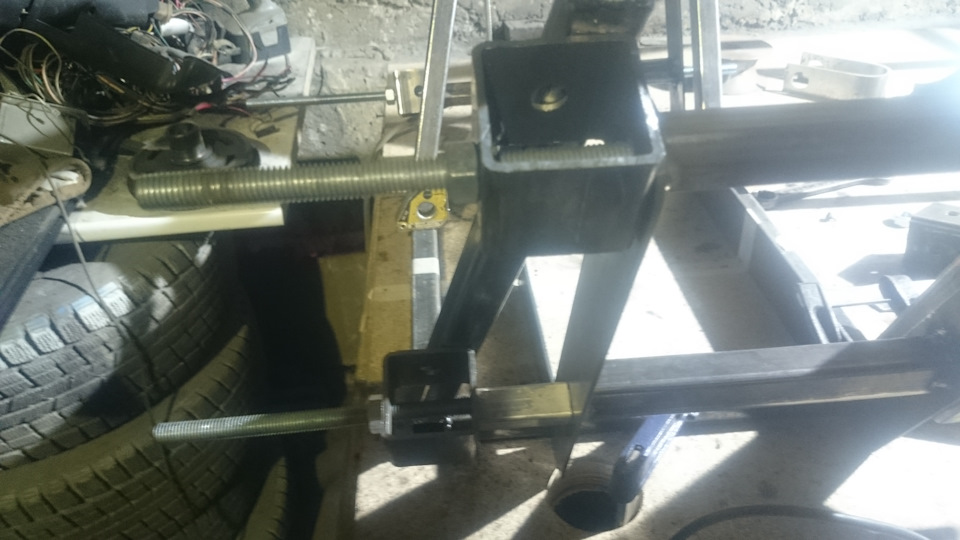

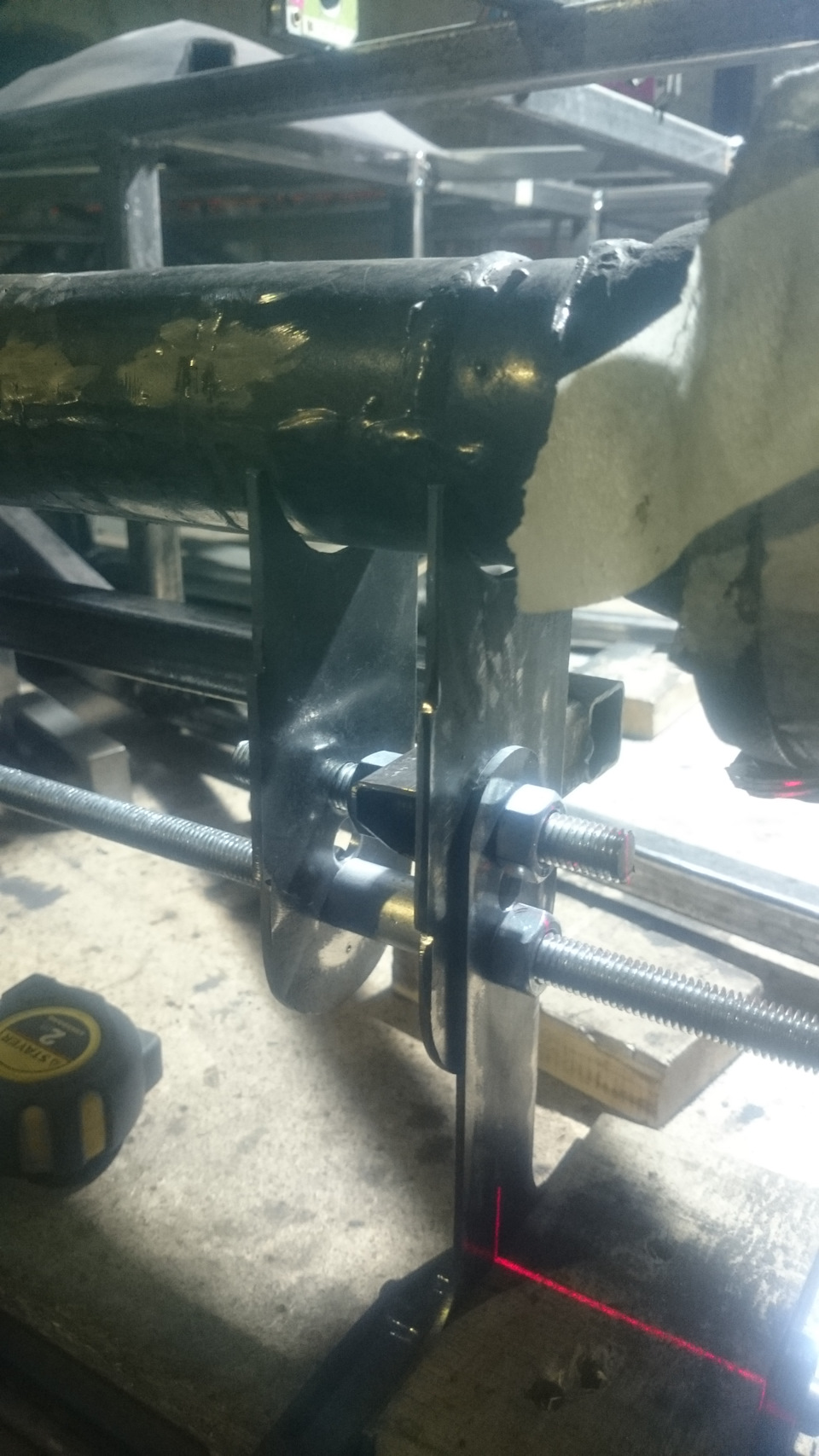

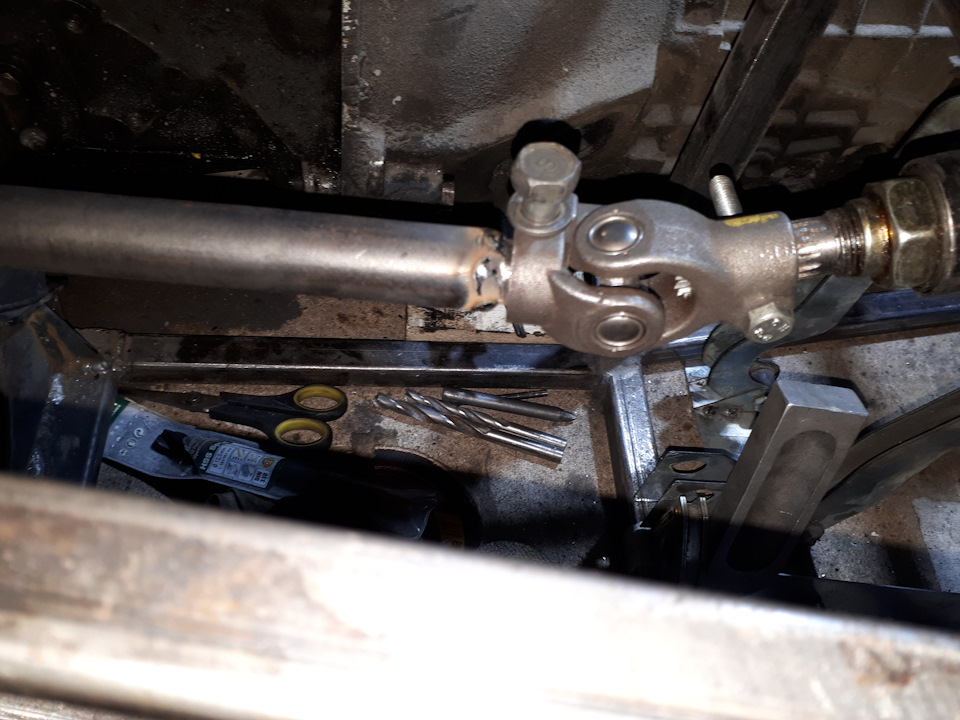

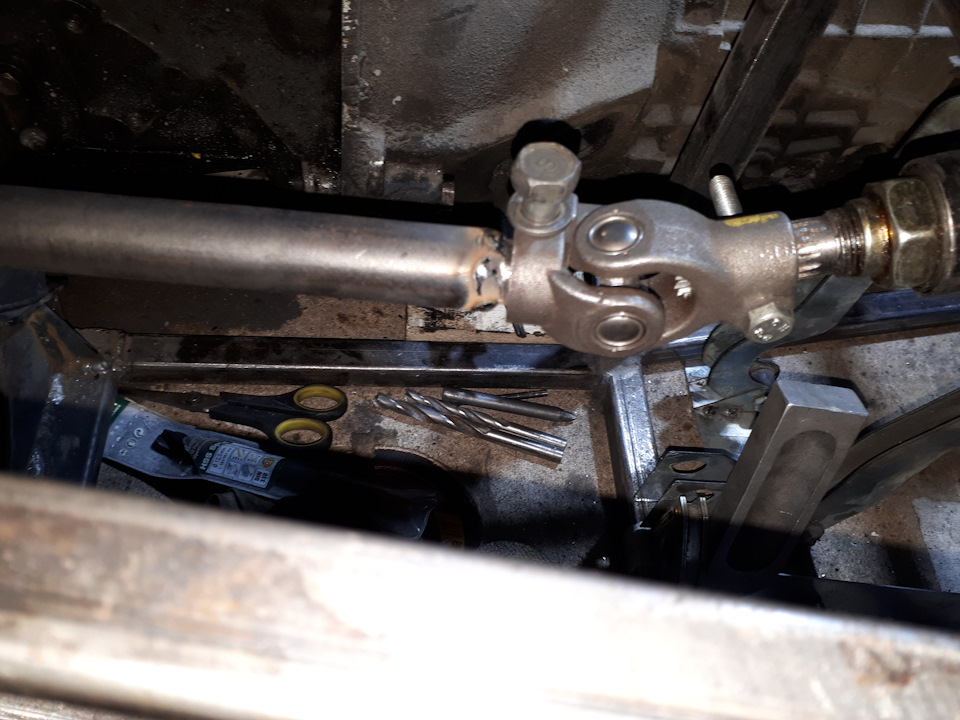

Will continue. At the moment I installed the steering column based on the arc of the 40mm pipe and the other end to the frame. To connect with the steering rack I bought crosses from Toyota and UAZ and bought the adjustable stock (with slots) from Nissan. Reduction bushings I machined Turner. And I welded the intermediate shaft.

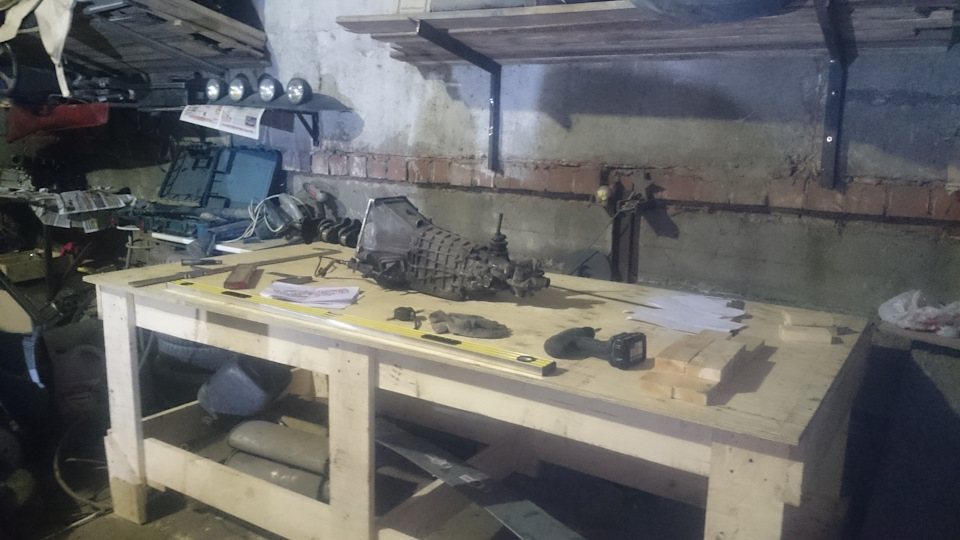

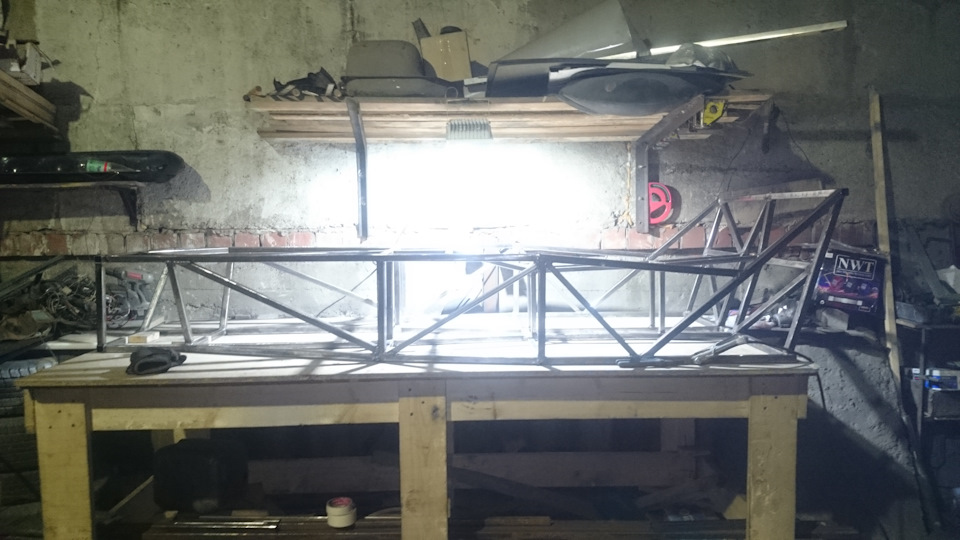

Now ordered a 50mm tube wall is 2mm the cage, waiting to be brought. Even put the motor and box. I want to finish the frame reinforcement that would not interfere. But it turned out that stock the exhaust manifold rests on the frame, want to buy a 4-1 exhaust tuning and all be customized. Still in the pedals, too, want to make homemade. For the fitting cut out of galvanized metal, it turned out that they are long, will have to redo the drawings))

Also wanted to ask the experts, a on the bottom is welded steel sheet, but I want to install an aluminum, how thick it is better to put?

|