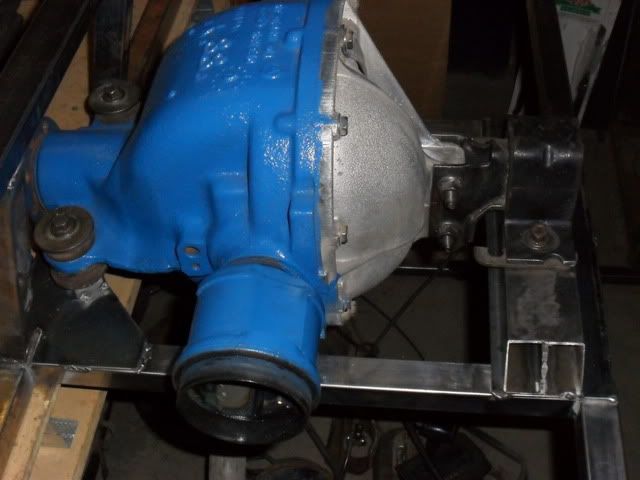

Well, what can I say, my family loves me. My wife gave me a free standing drill press, my brothers gave me a welding helmet and a circular saw, and my parents gave me a Stanley socket set. All will help with the build, thanks guys! Talking to a friend of a friend who just happens to be a welder, I also found out I was welding wrong, opps! Mainly I'm just tacking still, so it wasn't a big issue, but I was pushing the weld. He said, because I'm using flux-core, I should be pulling it, much easier to weld. Anyways, moving onto the car. I decided upon the set up for the diff., it is similar to what I had shown above with some small additions. I just added a tube to triangulate the corners at the front of the diff., reinforced it with a piece of flat steet and done. I still need to add the tubes for the suspensions mounts but I'm happy with the actual mounting design.

I also got the rest of the powertrain installed.

Input and output shafts are parrallel with a driveshaft angle of 6.5 degrees, I might have to lower that angle but I'm hope not!

I modified the stock motor mounts and fabricated some new legs so the engine sits at the correct height.

The Mustang II spindle package I ordered also arrived:

Next step(s) include welding in the rest of the frame, I'm missing quite a few triangulation tubes on the sides and rear, ordering some seats and rims, and starting on the rear suspension.

I was going to try these for seats,

Button, but now I'm not so sure. They aren't actually Bride seats, they are a copy and are made in Taiwan, hence the 80% reduction in price from actual Bride seats.